Chemical Resistant Fiberglass Floor Drain Grates can be adapted to meet every need and used for all types of industrial applications, because FRP floor gratings are more resistant to flexing and can bear a greater load than the usual plastic or metal gratings.

To meet the request of chemical resistant, the fiberglass drain grates need to use E-glass or S-glass fiberglass for production. E-Glass has been used extensively in polymer matrix composites, commonly termed “fiberglass”. These materials exhibit good mechanical properties, and chemical resistant. S-Glass is a kind of E-Glass, with higher tensile strength (modulus).

Frp drain gratings are made from fiberglass threads embedded in a solid grating mould after which they are topped with a high-quality resin. Curing then. FRP floor drain gratings have various styles, shapes, colors and sizes, with excellent corrosion and impact resistance which are ideal for corrosive environment, being widely used for chemical plants, aircraft construction, building, etc.

Some Applications of FRP floor grating:

• Chemical Storage Warehouse Walkways

• Stair Ladders

• Chemical Plant Platforms

• Plating Lines Trenches

• Catwalks

• Guards for Electrical Equipment and Machinery

• Boat or Offshore Oil Platform Decks

• Food Processing Plant Floorings

Fiberglass Drain Grating Features:

● Light weight

● Fire retardant

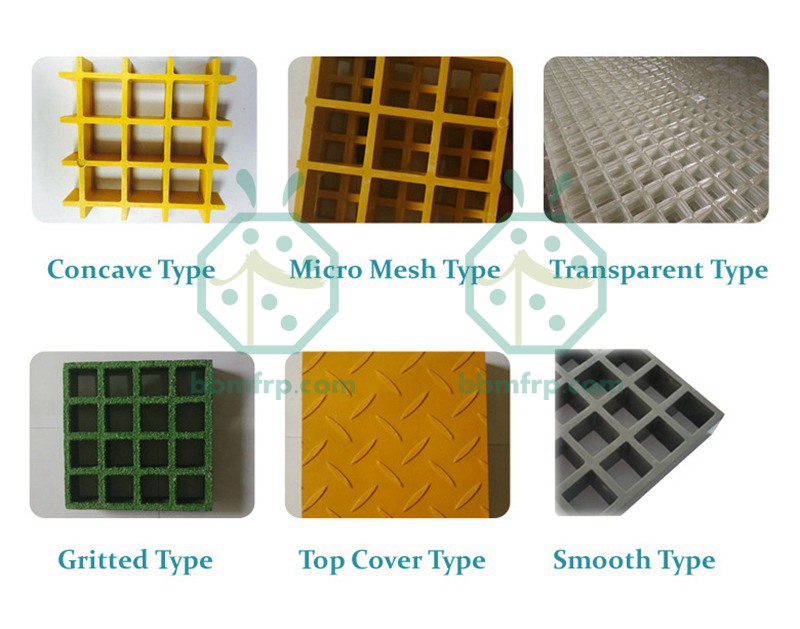

● Five types of surface for options

● Chemical resistant

● Electrically non-conductive

● Easy to cut and install

● Bi-directional strength: Most cutouts require no additional support

● Low maintenance cost● Low installation cost

● High impact resistance

Services From Your Frp Drain Grates Manufacturer:

● Customization of resin and fiberglass as per your project's request

● Free FRP grating samples for your checking and test.

● Customization of the colors and panel sizes as per your request

● Installation guide for your project

● Overseas transportation by sea freight or air freight.

Some Chemical Resistant FRP Floor Drain Grating Applications:

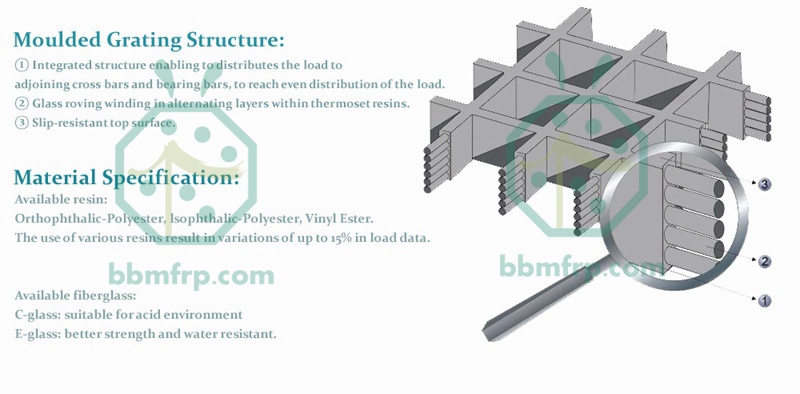

Molded FRP Platform Grating Structure:

Integrated structure enabling to distributes the load to adjoining cross bars and bearing bars, to reach even distribution of the load.

Glass roving winding in alternating layers within thermoset resins.

Slip-resistant top surface.

Other resins are available for your options too as per your request.

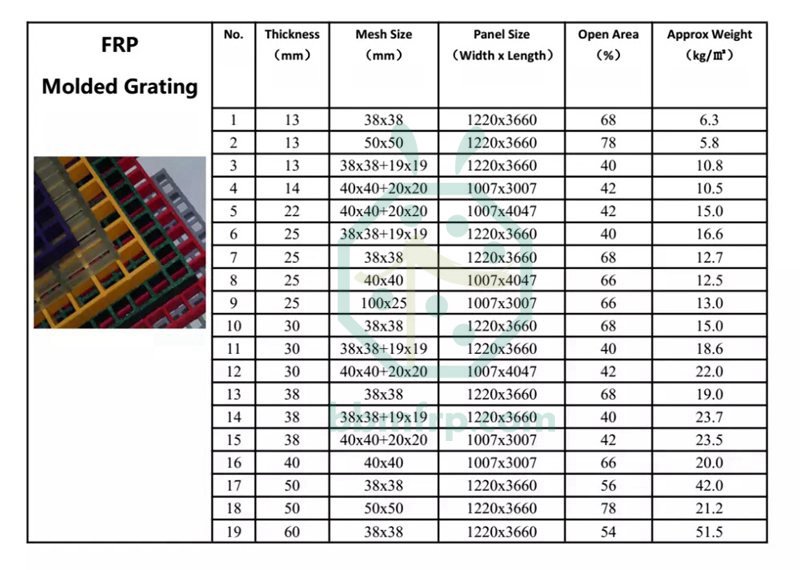

Specification of Composite Floor Grating:

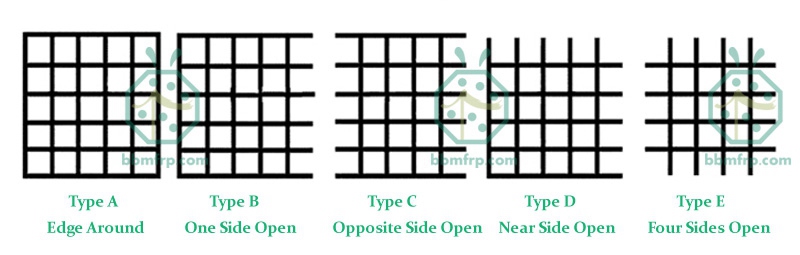

Five Cutting Methods of Composite Molded Gratings:

Various Surfaces Available:

Various Colors Available: