Heavy Duty FRP Grid Walkway is economical and practical to many applications like chemical industries, sewage plant, solar power station, paper plants and petroleum processing factories,due to its non-slip, fire retardant, non-corrosive, and non-conductive properties.

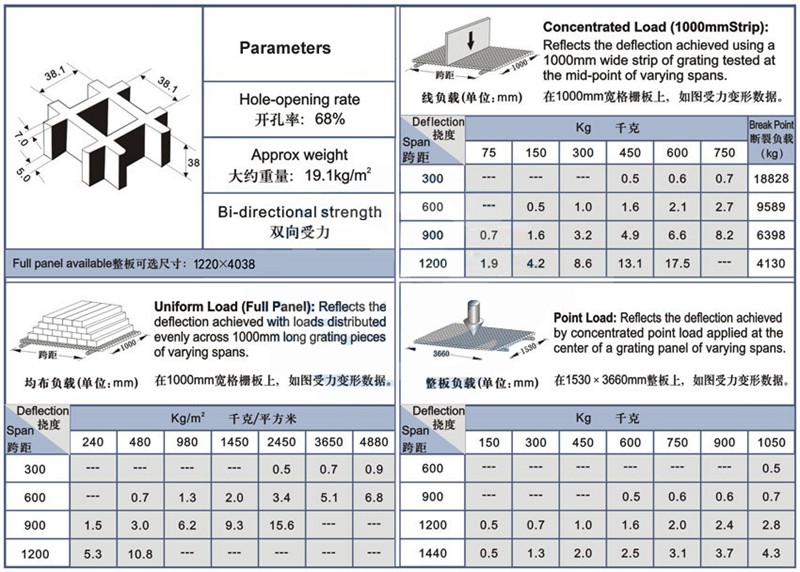

Heavy duty molded composite grating normally uses E-glass fibers for production, with thickness of 38mm or 50mm, bar size: 7/5mm, mesh size: 38x38mm. It could bear 6-7 tons load for 1 square meter, with 900mm span. It could bear 15-20 tons with 300mm span. Meanwhile, pultruded FRP grating could be an option too.

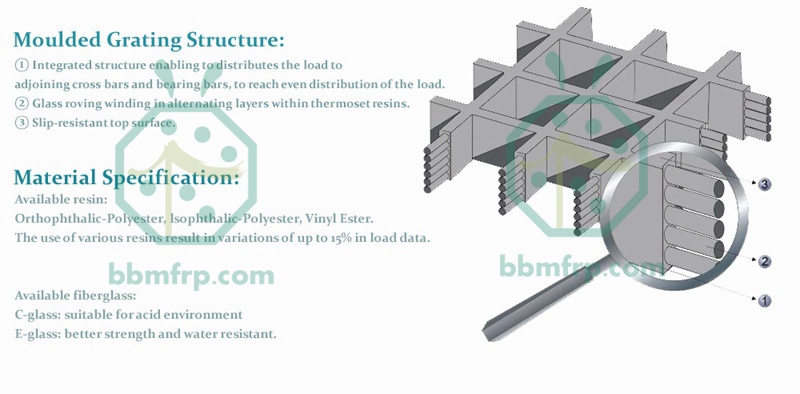

The standard resins used for heavy duty FRP gratings include Orthophthalic, Polyester resin, Isophthalic Polyester, Vinyl Ester resin. Vinyl Ester frp grating provides extremely high corrosion resistance.

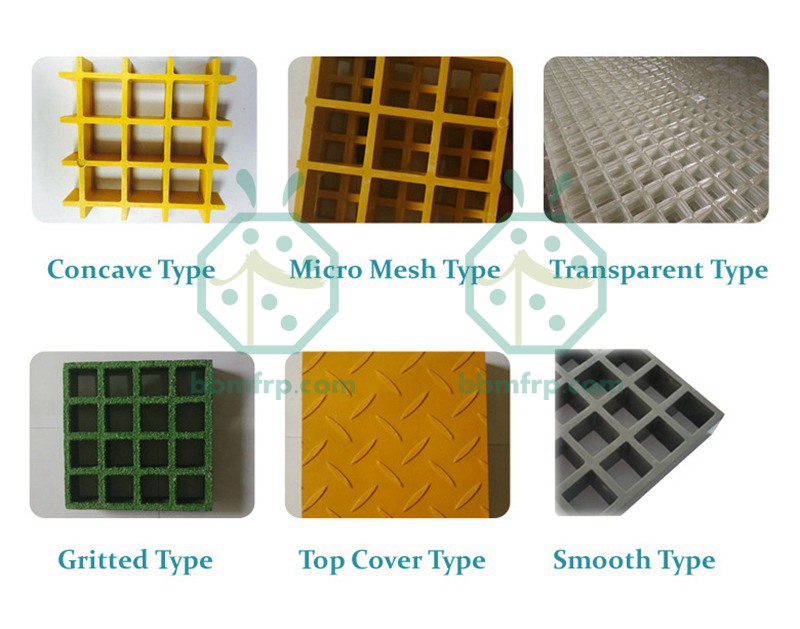

The surface of fiberglass plastic grating can be concaved top, smooth top, gritted surface, diamond top cover, etc.

Features:

● Light weight

● Fire retardant

● Five types of surface available

● Chemical resistant

● Electrically non-conductive

● Easy to cut and install

● Heavy duty

Application of heavy load frp grid:

● Storage warehouse

● Car wash

● Forklift and vehicular traffic

● Walkway platforms

● Manhole covers

● Other long span and heavy load areas

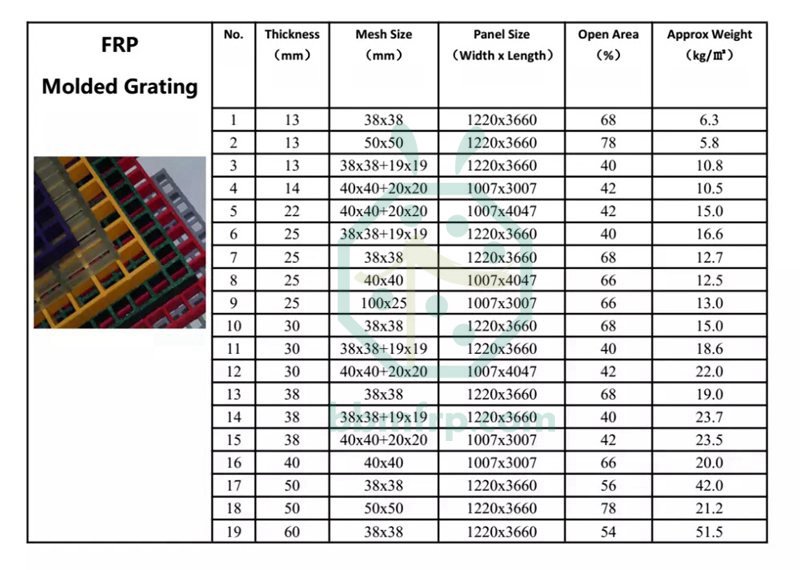

Parameters of heavy duty fiberglass grating:

Heavy Duty Car Wash FRP Platform Grating:

Heavy Duty Marine Platform Fiberglass Grating:

Molded FRP Grating Structure:

Other resins are available for your options too as per your request.

Specification:

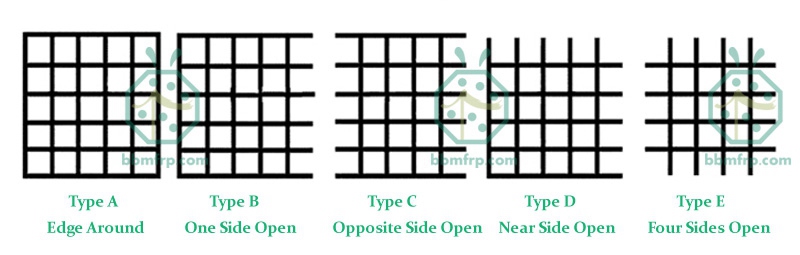

Five Cutting Methods:

Various Surfaces Available:

Various Colors Available: