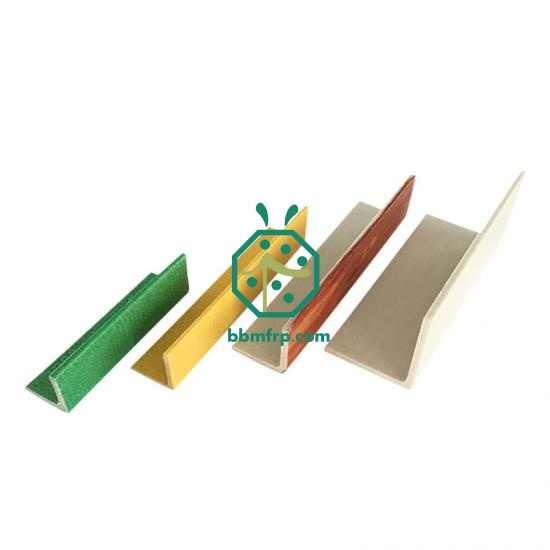

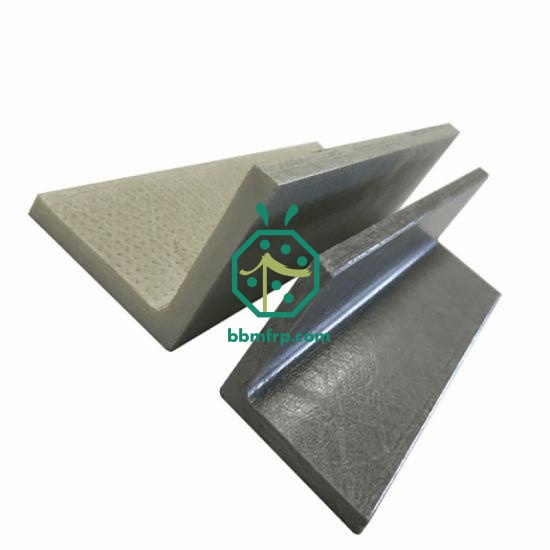

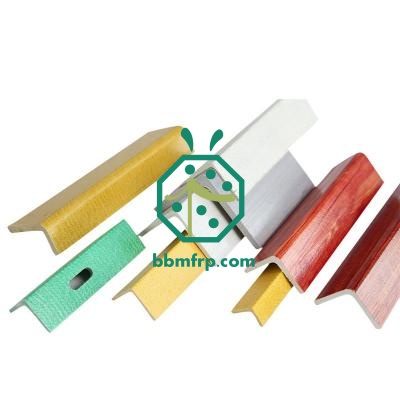

Petrochemical Plants Guardrail FRP Angle

The reinforced materials include fiberglass roving, continuous fiberglass mat, stitched fiberglass mat and surface veil etc. Unsaturated polyester resin, vinyl resin, phenolic resin are the major matrix materials. The angles are formed continuously after being heated by high temperature. They are widely used as the structure frame material when making the platforms and shelves.

Chemical Plant

Oil & Gas

Petrochemical & Refinery Plant

Fertilizer Plant

Marine Power Plant

Waste Water Treatment Plant

Desalination Plant

Cooling Tower

Shipyard

Advantages of FRP angles:

A. High strength

FRP is stronger than structural steel on a pound-for pound basis. It has been used to buildings, walkway, sub-floors and platforms.

B. Light weight

FRP is 20-25% the weight of steel and 70% the weight of aluminum. FRP are easily transported, handled and lifted into place. Total structures can often be preassembled and shipped to the job site ready to installation.

C. Anti-corrosion

FRP will not rot and are impervious to a broad range of corrosive elements. This feature makes FRP a natural selection for indoor or outdoor structures in pulp and paper mills, chemical plants, water and sewage treatment plants, structural near salt water and other corrosive environments.

D. Dimensional stability

The coefficient of thermal expansion of FRP is slightly less than steel and significantly less than aluminum.

E. Aesthetics

FRP are pigmented throughout the thickness of the part and can be made to virtually any desired custom color. Special surfacing veils are also available to create special surface appearances such as wood grain, marble, granite, etc.

F. Long service life

G. Long maintenance-free life

H. Easy to transport and fabricate