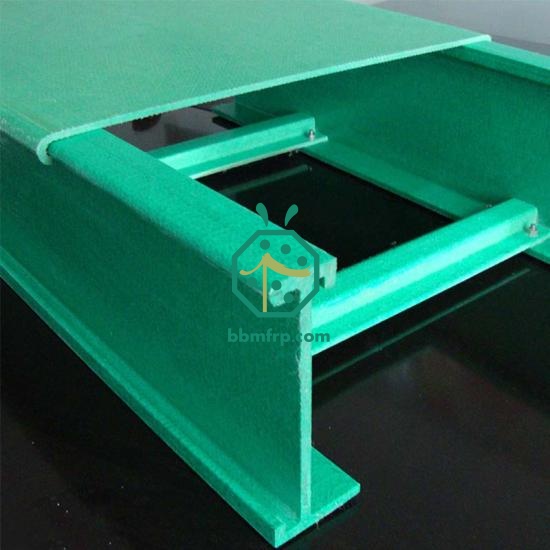

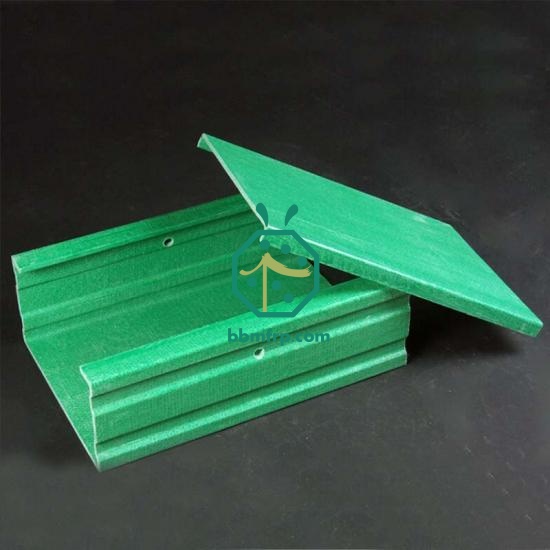

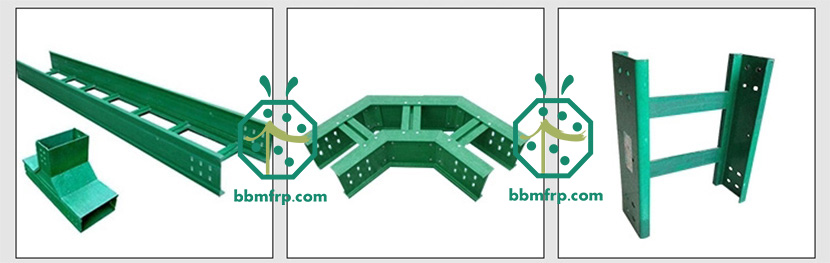

Easy Installation FRP Ladder Cable Trays

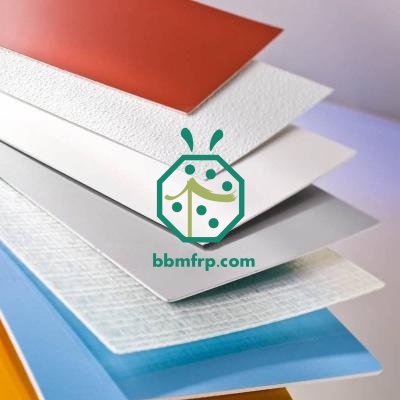

FRP ladder cable trays are made of glass fiber, epoxy resin and other special materials, with reasonable mechanical structure, light weight, high strength, corrosion resistance, flame retardant, aging resistance and good insulation properties, non-toxic, odorless, and long service life It is 5-6 times that of steel bridge. FRP ladder cable trays is easy to install and use, and can be installed with conventional hand tools. It is widely used in petroleum, chemical, electric power, light industry, television, telecommunications, etc.

FRP Ladder Cable Trays Advantages

1. Low cost, significant cost savings compared to standard traditional cable trays products.

2. Light in weight, wide range of sizes.

3. Fast heat dispersion.

4. Adapts to difficult architectural designs to accommodate changes in direction and elevation of cable runs.

5.Flexible, easy and fast installation.

6. Cables can be secured to clamps or ties.

7. Safe smooth edge design to protect cable.

8.Easy for line check and cleaning , easy maintained.

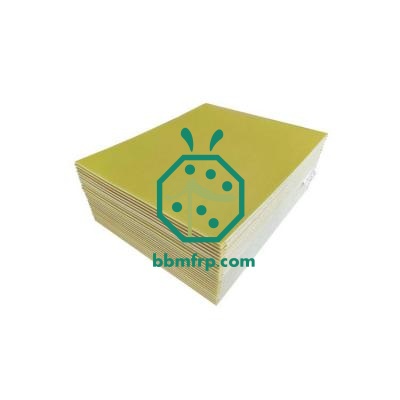

FRP Ladder Cable Trays Specification

| Title | Size(mm) | Remark |

| Width | 50,75,100,150,200,300,400,500,600,800,1000,1200 | custom |

| Height | 25,50,75,100,150,200 | custom |

| Length | 2000 | custom |

Application of Fiberglass Ladder Cable Tray

Industrial,Marine,Mining,Chemical,Oil & Gas,EMI / RFI Testing,Pollution Control,Pulp & Paper,Building Construction,Power Plants,Wastewater,Plating,Electrical,Offshore,Recreation,Metal Finishing,Water / Transportation,Radar,etc.

Notes

1. When the height is 50-100 mm, the two ends of the cable tray should be connected by 6 holes; when the height is 150-220 mm, the hole should be 12.

2. Support distance: should not be greater than the support distance and load capacity allowed by the load curve.

3. The width of the cable tray: When choosing the width of the cable tray, some obvious space should be left in order to add cables in the near future.

4. Laying separately: When cables and control cables are few, they can be placed in the same cable tray, as long as they are arranged separately with partitions.

5. Fix the cable: When placing the collected cable trays horizontally, the connection between the trays should be set to 1/4 of the jumper

For distance, horizontal cables should be fixed every 2 meters, and vertical cables should be fixed every 1.5 meters.

6. The cable bridge device should have additional grounding equipment.