Fiberglass roof panel is a composite material of polymer mixed with fibers such as fibreglass to enhance the strength and rigidity of fibres. FRP corrugated roof panel can also reduce the total weight of the roof. At the same time, FRP roofing is easy to install due to its lightweight and material itself is naturally corrosion resistance. The corrugated roof is produced in a constant size so that it can easily assemble and customized by cutting the desired size.

FRP roofing sheet is also much more economical compared to polycarbonate sheets and lesser maintenance is required. Similar to other polymer roofing sheet it is very good for long term energy cost savings.For factory workshop, as the Frp roofing is transparent, it has excellent light transmission, it is good for workers to work during the day. Various types of frp roof sheets are available for your workshop roofing construction.

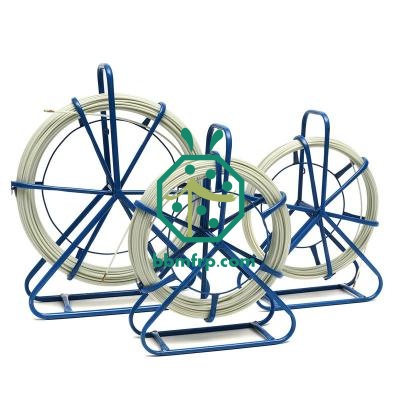

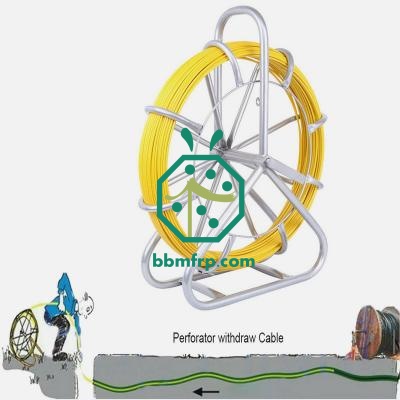

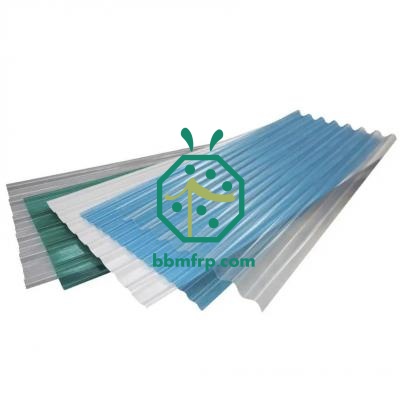

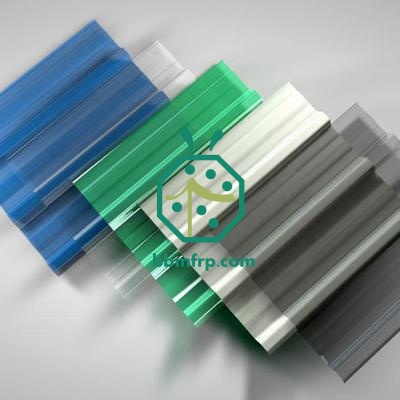

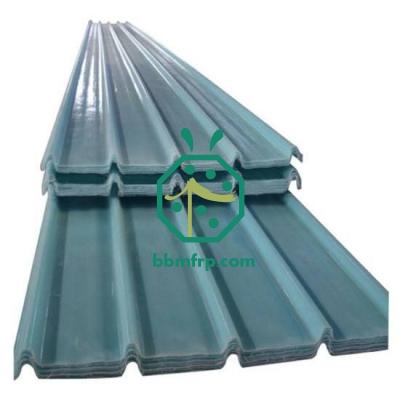

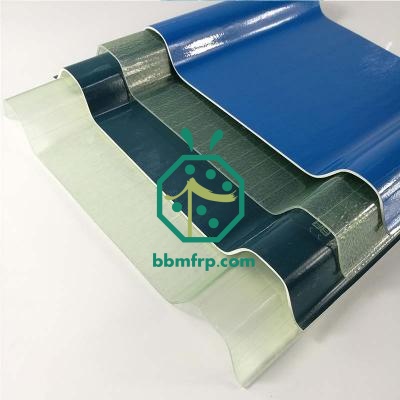

1. Product photos of transparent fiberglass roofing sheet:

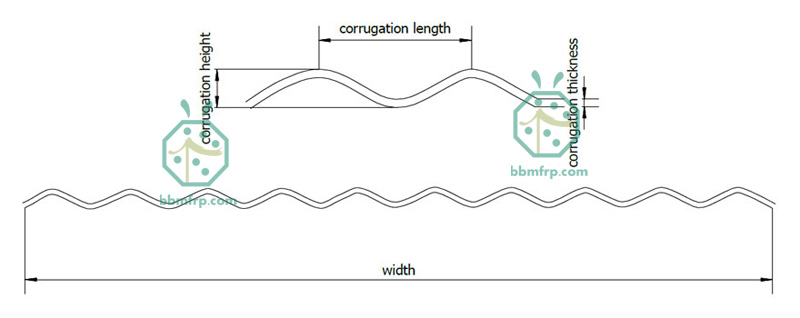

2. Parameters of frp transparent roofing sheet:

Cover Material

PET Film

Resin Material

UPR

Fiberglass

E-Glass

Anti-UV

≥99%

Weight

1.4kg/m2/mm

Temperature

-20ºC to 80ºC

Product Standard

GB/T-14206

Shear Strength

92 MPa

Tensile Strength

75 MPa

Flexural Strength

110 MPa

Thermal Conductivity

0.158 W/M·K

Thermal Coefficient

2.55x10-5 cm/cm/ºC

3. Features of fiberglass roofing panel:

a. Light transmission rate of 70-90%

b. Anti-aging

c. Good corrosion resistance

d. Excellent toughness

e. Working temperature: -40°c to+ 130 °c

f. Thickness:0.8-2.5mm

g. Excellent water resistance

h. Impact resistance and low temperature resistance

i. Light weight

j. Difficult to be burned

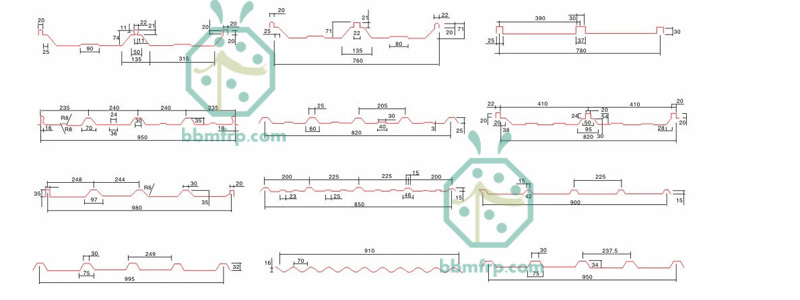

5. Regular profile of fiberglass roofing materials:

6. Application of fiberglass corrugated roofing:

Fiberglass roofing sheet could be used for the roofing construction of: Resident building; Vegetable greenhouse; Factory building; Farm product market; Farm house; Water resorts and cottages; Park shed; Bus station; Backyard pergola.